Difference: Digital printing uses computer digital control technology to directly print designs on fabrics, with richer pattern details and color layers.

Advantages: Accurate color, high precision, good repeatability, suitable for small batch production without MOQ, environmentally friendly.

Disadvantages: Relatively high production cost.

Difference: Rotary screen printing is a printing method that prints the printing pattern on screens, and then transfers ink to the fabric by rotating the rotary screen.

Advantages: Lower printing processing cost, good effect, suitable for large-scale production.

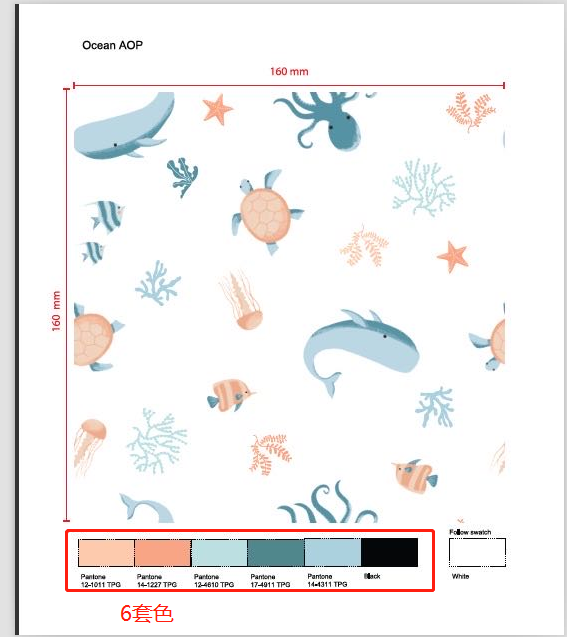

Disadvantages: The printing details and color layers are not rich enough, not suitable for complex patterns on textiles, and there is a certain minimum order quantity: generally 1500-2000 meters, and plate-making fees are required, generally 3-500 yuan/color set (if a pattern has 6 colors, then the plate-making fee is 6*300=1800 yuan).

Difference: Flat screen printing is a printing method that uses plain weave fabric as the basis.

Advantages: The printing processing cost is lower than rotary screen printing, and the printing effect is good. Smooth and flat fabrics can better display the printing pattern. Disadvantages: Not suitable for fabrics with texture, higher printing cost, there is a certain minimum order quantity, generally 1500-2000 meters, and plate-making fees are required, generally 3-500 yuan/color set (if a pattern has 6 colors, then the plate-making fee is 6*300=1800 yuan).

Difference: Heat transfer printing is a printing method that prints the printing pattern on thermal film, and then transfers the printing pattern to the fabric through high temperature and pressure.

Advantages: Lower printing processing cost, very fine and durable printing patterns, can be applied to various fabrics.

Disadvantages: The heat transfer printing equipment is relatively expensive, and the printing process requires more time than other methods. There is a certain minimum order quantity, generally 1500-2000 meters, and plate-making fees are required, generally 1600-2000 yuan/color set (if a pattern has 6 colors, then the plate-making fee is 6*1600=9600 yuan).

Difference: Transfer paper printing is a printing method that prints the printing pattern on special paper, and then transfers the printing pattern to the fabric through heat pressing. Advantages: Lower printing processing cost, good printing effect, can be applied to various fabrics.

Disadvantages: Transfer paper can only print one pattern at a time, not suitable for large-scale production. There is a certain minimum order quantity, generally 1500-2000 meters, and plate-making fees are required, generally 1600-2000 yuan/color set (if a pattern has 6 colors, then the plate-making fee is 6*1600=9600 yuan).

Mr Jack(GM)

We woven fabrics manufacturer from china over 16 years,we weave/dye/print ourselves.

Any woven fabrics inquiries please contact us ,we supply one-stop full series woven fabrics service.

Mob/whatsapp/wechat:+8615988150362

Mail: director@sixdragontextile.com

Hangzhou Six Dragon Textile Co.,ltd

http://www.sixdragontextile.com

Contact: Jack Wang

Phone: +86-15988150362

E-mail: gm@sixdragontextile.com

Add: 杭州六龙纺织品有限公司 Yuhang,Hangzhou,Zhejiang,China