What is yarn.

A continuous thin strip made up of textile fibers with certain mechanical properties, fineness and softness.

Since there are long and short textile fibers, the yarn formation method has its own differences. They have their own yarn formation systems, and those formed by long fibers are called filament yarns, and those formed by short fibers are called short fiber yarns.

There are many ways to classify yarns, which can be divided into different types according to different requirements.

Based on the geometric structure of the fibers they can be divided into two broad categories: short fibers and filaments

According to the source of fiber can be divided into two major categories: natural fiber and chemical fiber

Staple fiber spinning process

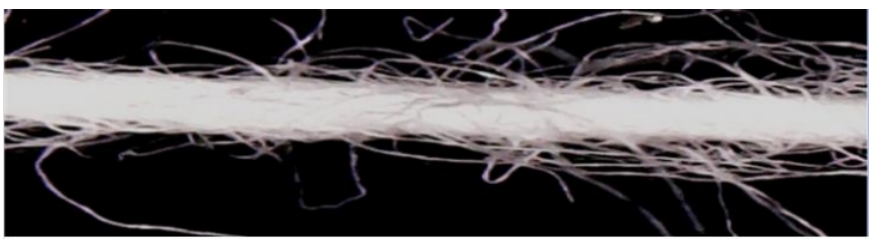

Fibers are twisted and stretched to form a strip state with a certain shape.

Yarn (microscopic)

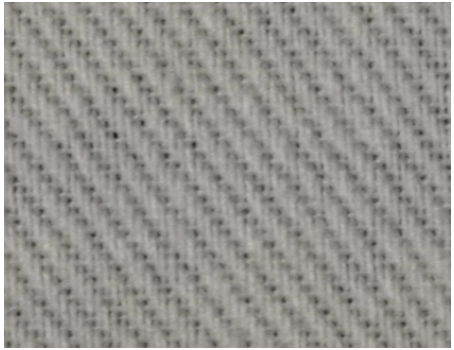

Difference between combed and combed yarns

Staple fiber spinning method - ring spinning

I. Ring spinning.

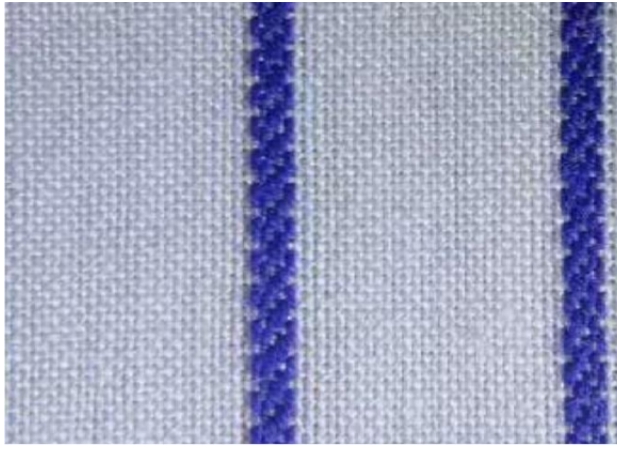

Ring spinning is a mechanical spinning method in which spindles and steel collars and wire rings are twisted and drawn by rollers. Ring spinning for the fiber is mostly inside and outside the transfer of the conical spiral state, so that the fiber in the yarn inside and outside the winding association, the yarn structure is tight, high strength. Suitable for yarn making and various products such as weaving and knitting. Ring spun yarn sample style characteristics flat surface, clear twill pattern

Advantages of ring spinning: good handfeel, any yarn count, high yarn strength. Disadvantages of ring spinning: complicated process, low output, relatively high price.

Second, compact spinning.

Compact spinning is also known as solid and dense spinning, compression spinning, cohesive spinning. It is in the ring spinning machine by the transformation of its core technology is in the front roller output end to add a gathering device, so that the whiskers after gathering and then output twisting. The yarn is tight, with a clean appearance and less hairiness, especially over 3mm hairiness is reduced by 70%. The special strength of the same yarn is increased by 5-10%.

Sai Lo spinning: Sai Lo spinning is also known as parallel twist spinning, known as A, B yarn in China, modern is called Sai Lo spinning. After drafting, the front roller outputs the two single yarn strips with a small amount of twist due to the transfer of twist, which is then further twisted into a strand-like yarn. The yarn is characterized by uniform dryness, low hairiness and high strength. Sai luo spinning yarn woven fabric feel soft, good breathability.

Fourth, tightly packed cyclo spinning.

Tightly spun cycloid is in the cycloid spinning spinning machine to add a suction wind gathering device. The yarn is evenly dried and has less hairiness. It combines the advantages of both cyclo-spinning and compact spinning.

V. Strand.

Strands are made of two or more single yarns twisted together. Its strength and abrasion resistance is better than single yarn. At the same time, the strands can be combined and twisted in a certain way to obtain double twisted strands, such as double strands, triple strands and multi-stranded strands. Mainly used for sewing thread, knitting thread and medium-thick strong fabrics.

Six, airflow spinning.

Flow spinning is also known as rotor spinning. Airflow spinning is the airflow way to transport fibers, by one end of the grip twisting. Generally speaking, ring spun yarn less hairiness, higher strength, better quality. The air flow spinning process is short, the raw material is more short pile, the yarn is hairy, and the count and twist cannot be very high. The spinning speed is faster. The price is also lower. In terms of yarn structure, ring spun yarns are tighter, while air spun yarns are fluffier, coarser, and more rugged in style, making them more suitable for denim. Advantages of ring spinning: simple process, high yield and low price. Disadvantages of ring spinning: poor handfeel, loose yarn, low strength. Seven, vortex spinning: vortex spinning is the use of air vortex on the open fiber cohesion twisting, so that the yarn into a spinning method. Vortex spinning using raw materials to synthetic fibers and viscose fibers, if blended with cotton cotton fiber proportion should not exceed 30%. Vortex spinning yarn woven fabric feel rough, anti-pilling effect is very good. Yarn count range, only low and medium count yarn, suitable for pile products.

Filament yarn

Monofilament: Long length of continuous single fiber. For example, a single filament formed by a single hole of chemical fiber spray.

Compound filament: A bundle of two or more monofilaments combined together. For example: chemical fiber a spout several spout holes out and together in the filament; several cocoon silk by reeling and combined to get the raw silk.

Twisted silk: formed by twisting the compound silk.

Compound twisted silk: twisted silk is formed by merging and twisting once or more times.

Deformed yarn: the original chemical fiber yarn is deformed to have the appearance of curls, spirals, loops and other properties, and presents fluffiness, stretchability.

Monofilament

The monofilament of chemical fiber is mainly nylon, generally below 30D. Polyester also has monofilament, but not many applications. ▶ In knitting production, monofilament can be used directly to knit socks, scarves, and other fabrics. ▶ Monofilament yarns are generally used less directly in woven fabric production. Eugenics yarn is woven with monofilament. ▶ Except for special requirements, compound silk is generally used more often as woven material

Compound filaments

The monofilaments in a compound yarn can be unbound or bound, depending on the filament yarn processing process and the style requirements of the product.

There are three ways to form a lateral binding force: ① twisting the single fiber bundles together, i.e., twisted filaments; ② intermittent injection of high pressure or high temperature gas flow from the side to the traveling filament bundle during post-spinning or pre-woven processing, so that local sections of the filament bundle can be interspersed or bonded to each other to form a network of filaments; ③ by means of bonding substances (silk glue, sheaths, pulp) to make the monofilaments bondable. The monofilament fibers are bonded together by means of a bonding substance (silk glue, silk sheath, sizing), i.e. sizing. For example, silk filament yarn, sizing filament yarn.

@sixdragontextile-Middle and high-end woven fabrics manufacturer

Contact: Jack Wang

Phone: +86-15988150362

E-mail: gm@sixdragontextile.com

Add: 杭州六龙纺织品有限公司 Yuhang,Hangzhou,Zhejiang,China