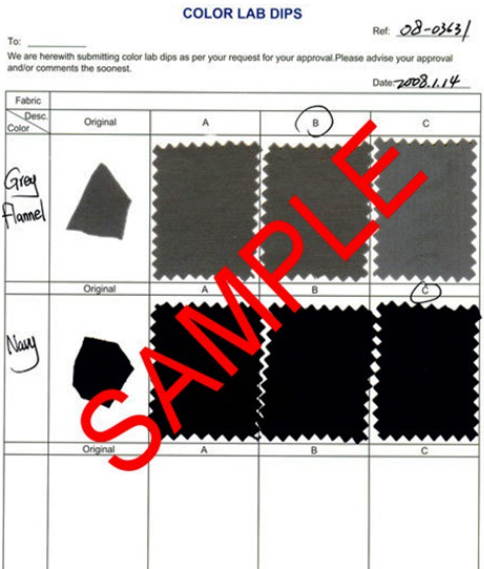

Fabric color lap dips are an essential part of the textile manufacturing process. They are small samples of fabric that are dyed in different colors to show the range of colors that can be achieved for a particular fabric. These samples are used by textile manufacturers to select the desired color for their products before starting the bulk production. The lap dips are usually created by dyeing a small piece of fabric in different shades of a particular color and are presented to the customer for approval. This process helps to ensure that the final product meets the customer's expectations in terms of color and quality.

The importance of fabric color lap dips cannot be overstated. They play a crucial role in the textile manufacturing process, as they help manufacturers to select the right color for their products. The process of creating lap dips involves dyeing a small piece of fabric in different shades of a particular color. This allows manufacturers to see how the color will look on the fabric and make any necessary adjustments before starting the bulk production. The process of creating lap dips is not as simple as it may seem. It requires a lot of skill and expertise to get the right color and shade. The dyeing process involves a lot of trial and error, as manufacturers have to experiment with different dye concentrations and temperatures to get the desired color. This process can be time-consuming and expensive, but it is essential to ensure that the final product meets the customer's expectations. There are several factors that manufacturers need to consider when creating fabric color lap dips. The first factor is the type of fabric that is being used. Different fabrics react differently to dyes, and some fabrics may require a different dyeing process than others. The second factor is the type of dye that is being used. There are many different types of dyes available, and each type of dye has its own unique properties. The third factor is the color that is being used. Different colors require different dye concentrations and temperatures to achieve the desired shade. Once the lap dips have been created, they are presented to the customer for approval. The customer can then select the desired color for their product, and the bulk production can begin. The lap dips serve as a reference for the manufacturer throughout the production process, ensuring that the final product meets the customer's expectations. In conclusion, fabric color lap dips are an essential part of the textile manufacturing process. They help manufacturers to select the right color for their products and ensure that the final product meets the customer's expectations. The process of creating lap dips is not as simple as it may seem, and it requires a lot of skill and expertise to get the right color and shade. Despite the challenges involved, lap dips remain an indispensable tool for textile manufacturers, and they will continue to play a crucial role in the industry for years to come.

Contact: Jack Wang

Phone: +86-15988150362

E-mail: gm@sixdragontextile.com

Add: 杭州六龙纺织品有限公司 Yuhang,Hangzhou,Zhejiang,China